Making a 360-Degree Transformation

from an Assembly Plant into a

Manufacturing Company

Making a 360-Degree Transformation from an Assembly Plant into a Manufacturing Company

Making a 360-Degree Transformation from an Assembly Plant into a Manufacturing Company

Honda Motors was one of the earliest multinationals to set up its manufacturing facilities in India. When it entered India, Honda Motors also brought Keihin Corporation—its top vendor of hi-tech and critical systems in Japan. Keihin Corporation, Honda’s largest subsidiary for manufacturing automotive air-conditioning systems in India, chose to partner with Panalfa. With this, Keihin Panalfa was born.

Together, Keihin Corporation and Panalfa, played an integral role in Honda’s successes in India.

The execution

strategy

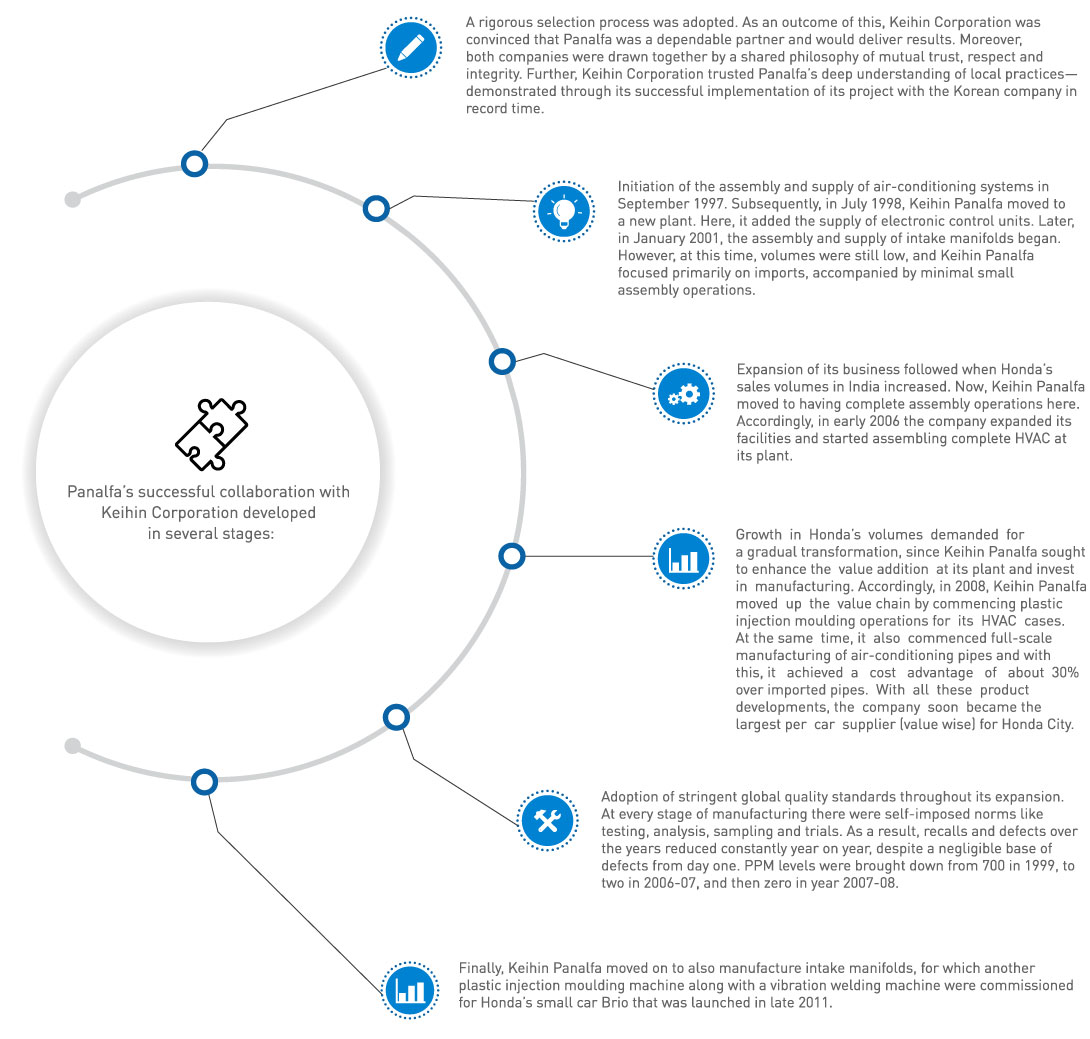

Panalfa’s successful collaboration with Keihin Corporation developed in several stages:

A rigorous selection process was adopted. As an outcome of this, Keihin Corporation was convinced that Panalfa was a dependable partner and would deliver results. Moreover, both companies were drawn together by a shared philosophy of mutual trust, respect and integrity. Further, Keihin Corporation trusted Panalfa’s deep understanding of local practices—demonstrated through its successful implementation of its project with the Korean company in record time.

Initiation of the assembly and supply of air-conditioning systems in September 1997. Subsequently, in July 1998, Keihin Panalfa moved to a new plant. Here, it added the supply of electronic control units. Later, in January 2001, the assembly and supply of intake manifolds began. However, at this time, volumes were still low, and Keihin Panalfa focused primarily on imports, accompanied by minimal small assembly operations.

Expansion of its business followed when Honda’s sales volumes in India increased. Now, Keihin Panalfa moved to having complete assembly operations here. Accordingly, in early 2006 the company expanded its facilities and started assembling complete HVACat its plant.

Growth in Honda’s volumes demanded for a gradual transformation,since Keihin Panalfa sought to enhance the value addition at its plant and invest in manufacturing. Accordingly, in 2008, Keihin Panalfa moved up the value chain by commencing plastic injection moulding operations for its HVAC cases. At the same time, it also commenced full-scale manufacturing of air-conditioning pipes and with this, it achieved a cost advantage of about 30% over imported pipes. With all these product developments, the company soon became the largest per car supplier (value wise) for Honda City.

Adoption of stringent global quality standards throughout its expansion. At every stage of manufacturing there were self-imposed norms like testing, analysis, sampling and trials. As a result, recalls and defects over the years reduced constantly year on year, despite a negligible base of defects from day one. PPM levels were brought down from 700 in 1999, to two in 2006-07, and then zero in year 2007-08.

Finally, Keihin Panalfa moved on to also manufacture intake manifolds, for which another plastic injection moulding machine along with a vibration welding machine were commissioned for Honda’s small car Brio that was launched in late 2011.

Panalfa’s successful collaboration with Keihin Corporation developed in several stages:

A rigorous selection process was adopted. As an outcome of this, Keihin Corporation was convinced that Panalfa was a dependable partner and would deliver results. Moreover, both companies were drawn together by a shared philosophy of mutual trust, respect and integrity. Further, Keihin Corporation trusted Panalfa’s deep understanding of local practices—demonstrated through its successful implementation of its project with the Korean company in record time.

Initiation of the assembly and supply of air-conditioning systems in September 1997. Subsequently, in July 1998, Keihin Panalfa moved to a new plant. Here, it added the supply of electronic control units. Later, in January 2001, the assembly and supply of intake manifolds began. However, at this time, volumes were still low, and Keihin Panalfa focused primarily on imports, accompanied by minimal small assembly operations.

Expansion of its business followed when Honda’s sales volumes in India increased. Now, Keihin Panalfa moved to having complete assembly operations here. Accordingly, in early 2006 the company expanded its facilities and started assembling complete HVACat its plant.

Growth in Honda’s volumes demanded for a gradual transformation,since Keihin Panalfa sought to enhance the value addition at its plant and invest in manufacturing. Accordingly, in 2008, Keihin Panalfa moved up the value chain by commencing plastic injection moulding operations for its HVAC cases. At the same time, it also commenced full-scale manufacturing of air-conditioning pipes and with this, it achieved a cost advantage of about 30% over imported pipes. With all these product developments, the company soon became the largest per car supplier (value wise) for Honda City.

Adoption of stringent global quality standards throughout its expansion. At every stage of manufacturing there were self-imposed norms like testing, analysis, sampling and trials. As a result, recalls and defects over the years reduced constantly year on year, despite a negligible base of defects from day one. PPM levels were brought down from 700 in 1999, to two in 2006-07, and then zero in year 2007-08.

Finally, Keihin Panalfa moved on to also manufacture intake manifolds, for which another plastic injection moulding machine along with a vibration welding machine were commissioned for Honda’s small car Brio that was launched in late 2011.

The

Panalfa edge

Starting with the assembly and supply of air-conditioning systems in 1997, Keihin Panalfa had come a long way in just over a decade. With its foray into manufacturing, it also introduced intake manifolds in plastic injection moulding for the first time in India.

With this, Keihin Panalfa made a 360-degree transformation from being a part assembly company, to a full assembly company, and then becoming a full-fledged manufacturing company. Accompanied by a consistent increase in sales, Keihin Panalfa was trusted for its quality, cost efficiency, delivery and consistency.