Pioneering New Technology

to Drive Customer Success

Pioneering New Technology

to Drive Customer Success

Pioneering New Technology to Drive Customer Success

In 2008, Panalfa Autoelektrik introduced reduction gear starter motors for tractors and stationary engines for the first time in India. Prior to this, customers used direct drive technology. However, Panalfa’s assessment indicated that reduction gear starter motors had numerous advantages for customers— including highly efficient reduction gear pinion drive assembly, reduced weight and dimensions, high torque for specific power output, increased efficiency with low current drain from battery, low maintenance costs and easy serviceability. But the Indian market was dominated by few large players, including global companies like Bosch and Lucas that offered reduction gear technology elsewhere in the world, but had not introduced this in India since the change in technology required heavy investments and time and effort to obtain approvals from customers.

When Panalfa first approached customers with reduction gear starter motors, they were reluctant to experiment with this new technology as it involved a lengthy and expensive approval process, and no one wanted to be the first one to experiment. Another issue was that tractors were being sold by these companies across the country, reaching even the remotest villages. These required an immediate after-sales service network, especially when crops were sown or harvested. Manufacturers also had to ensure the availability of spare parts and service backup within 50 kms of any tractor user. Panalfa was undecided about setting up this vast network, without any existing orders, since it was a time consuming and expensive proposition.

The execution

strategy

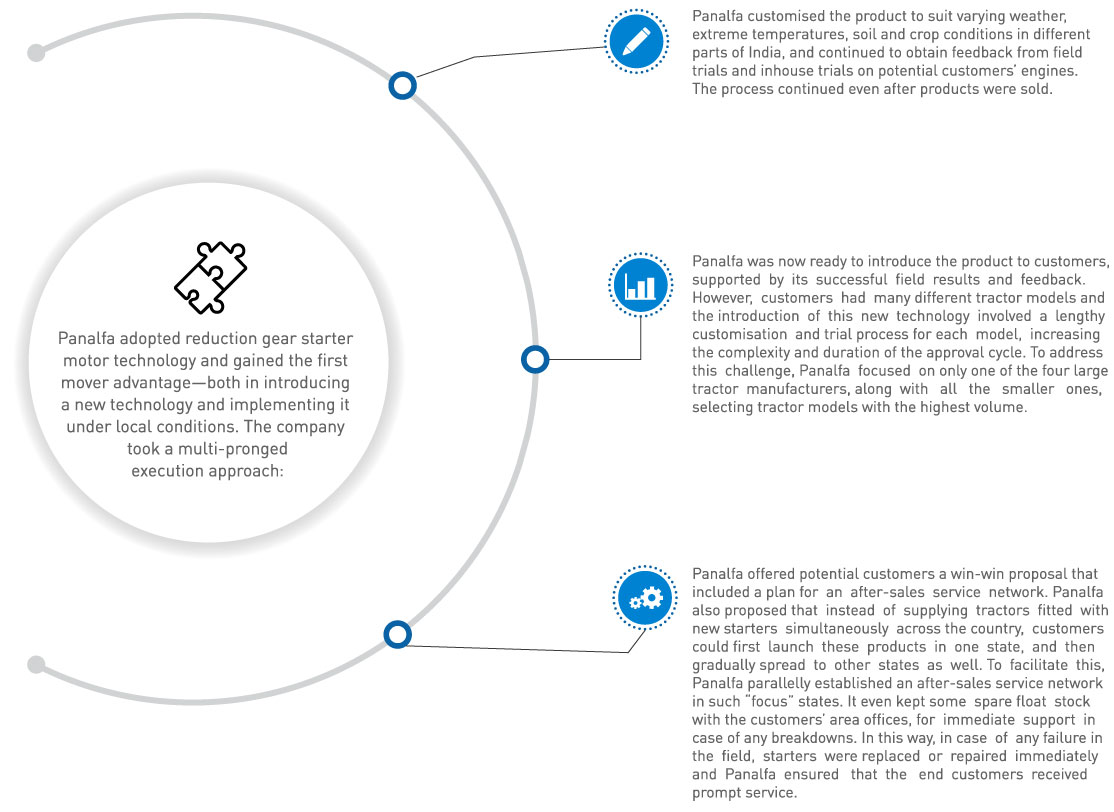

Panalfa adopted reduction gear starter motor technology and gained the first mover advantage—both in introducing a new technology and implementing it under local conditions. The company took a multi-pronged execution approach:

Panalfa customised the product to suit varying weather, extreme temperatures, soil and crop conditions in different parts of India, and continued to obtain feedback from field trials and inhouse trials on potential customers’ engines. The process continued even after products were sold.

Panalfa was now ready to introduce the product to customers, supported by its successful field results and feedback. However, customers had many different tractor models and the introduction of this new technology involved a lengthy customisation and trial process for each model, increasing the complexity and duration of the approval cycle. To address this challenge, Panalfa focused on only one of the four large tractor manufacturers, along with all the smaller ones, selecting tractor models with the highest volume.

Panalfa offered potential customers a win-win proposal that included a plan for an after-sales service network. Panalfa also proposed that instead of supplying tractors fitted with new starters simultaneously across the country, customers could first launch these products in one state, and then gradually spread to other states as well. To facilitate this, Panalfa parallelly established an after-sales service network in such “focus” states. It even kept some spare float stock with the customers’ area offices, for immediate support in case of any breakdowns. In this way, in case of any failure in the field, starters were replaced or repaired immediately and Panalfa ensured that the end customers received prompt service.

Panalfa adopted reduction gear starter motor technology and gained the first mover advantage—both in introducing a new technology and implementing it under local conditions. The company took a multi-pronged execution approach:

Panalfa customised the product to suit varying weather, extreme temperatures, soil and crop conditions in different parts of India, and continued to obtain feedback from field trials and inhouse trials on potential customers’ engines. The process continued even after products were sold.

Panalfa was now ready to introduce the product to customers, supported by its successful field results and feedback. However, customers had many different tractor models and the introduction of this new technology involved a lengthy customisation and trial process for each model, increasing the complexity and duration of the approval cycle. To address this challenge, Panalfa focused on only one of the four large tractor manufacturers, along with all the smaller ones, selecting tractor models with the highest volume.

Panalfa offered potential customers a win-win proposal that included a plan for an after-sales service network. Panalfa also proposed that instead of supplying tractors fitted with new starters simultaneously across the country, customers could first launch these products in one state, and then gradually spread to other states as well. To facilitate this, Panalfa parallelly established an after-sales service network in such “focus” states. It even kept some spare float stock with the customers’ area offices, for immediate support in case of any breakdowns. In this way, in case of any failure in the field, starters were replaced or repaired immediately and Panalfa ensured that the end customers received prompt service.

The

Panalfa edge

With the introduction of new reduction gear starter motors technology, Panalfa disrupted the entire market and soon competitors were also forced to follow suit.

Moreover, Panalfa expanded its reach across the county, supported by latest technology, quality, after-sales support, customer satisfaction and client relationships. As a result, Panalfa Autoelektrik drove its market share from 9 per cent in the first three years to 27 per cent in the following three years. Its share of business from some of its key customers rose to 90 percent within just three years of starting supplies to them. All these shares were taken from large established players.