Driving Rapid Localisation

of Automobile Components

Driving Rapid Localisation

of Automobile Components

Driving Rapid Localisation of Automobile Components

In 1995, global automobile company Daewoo Motors saw a great opportunity in the emerging Indian automobile market. It wanted to introduce a top quality range of passenger vehicles in India. To achieve this and to meet its indigenisation targets, which were a part of its phased manufacturing commitment to the Indian government, Daewoo needed Indian companies that could manufacture high-technology auto components and systems at affordable prices. Panalfa was one of four partners selected to supply most of its high-technology, value-added products, and this led to the incorporation of Panalfa Dongwon, as a joint venture with Daewoo and its supplier company Dongwon Metal in Korea.

On February 3, 1996, the joint venture agreement—between Panalfa, Daewoo Motors and Dongwon Metal was signed. The agreement included a challenging timeline, with Panalfa Dongwon undertaking to initiate the provision of supplies to Daewoo by March 31, 1996. If Panalfa Dongwon did not achieve this within two months, Daewoo would incur huge penalties. Panalfa Dongwon accepted the challenge and the countdown began.

The execution

strategy

In 1996, India was one of the most difficult countries to set up a new business as it was characterised by complex procedures, difficult approvals, and delayed timelines. But Panalfa set up its new joint venture in record time. It not only fast-tracked the infrastructure setup for the manufacturing plant, but also recruited the right talent, adopted cutting-edge technology, and streamlined the supply chain.

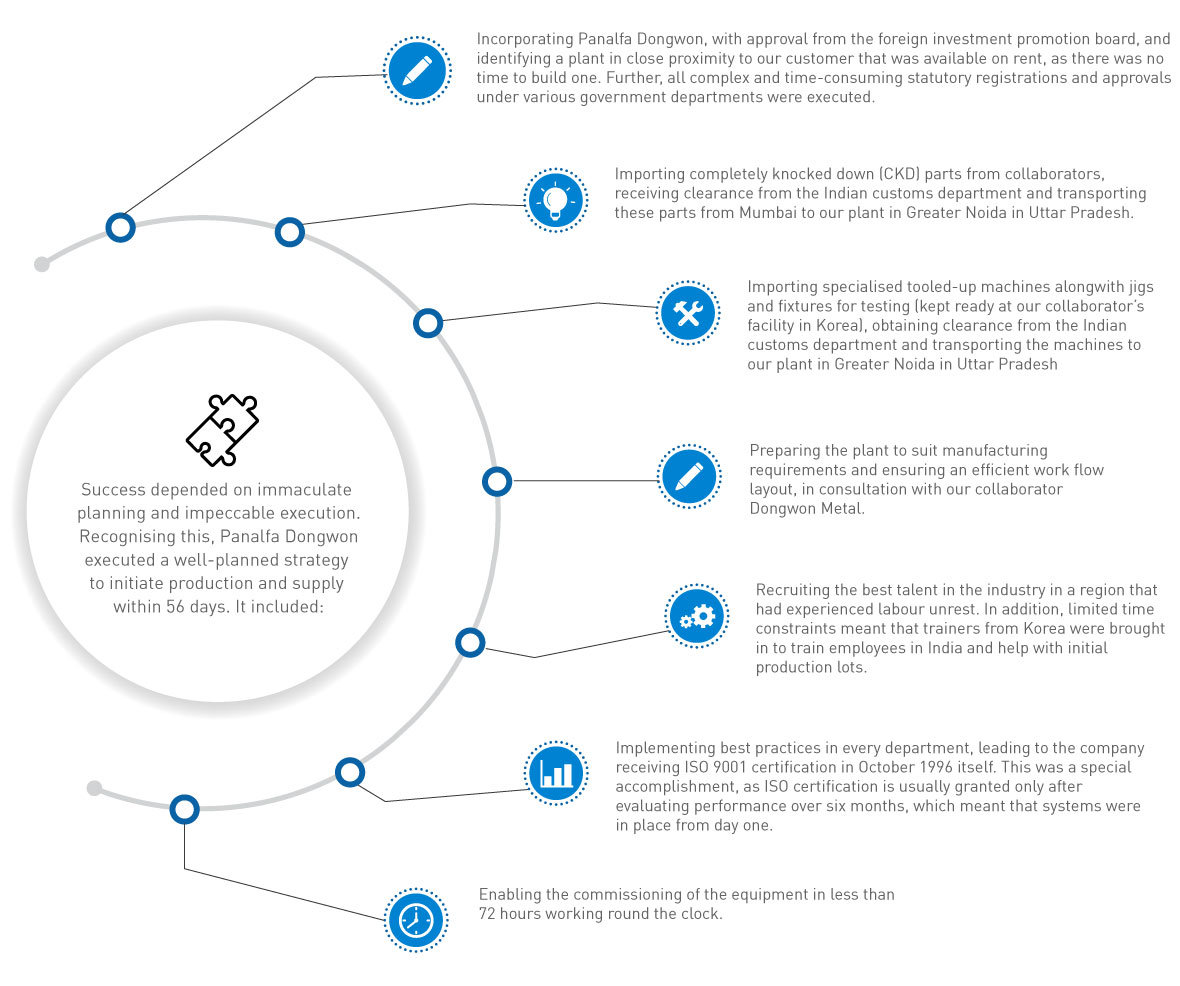

Success depended on immaculate planning and impeccable execution. Recognising this, Panalfa Dongwon executed a well-planned strategy to initiate production and supply within 56 days. It included:

Incorporating Panalfa Dongwon, with approval from the foreign investment promotion board, and identifying a plant in close proximity to our customer that was available on rent, as there was no time to build one. Further, all complex and time-consuming statutory registrations and approvals under various government departmentswereexecuted.

Importing completely knocked down (CKD) parts from collaborators, receiving clearance from the Indian customs department and transporting these parts from Mumbai to our plant in Greater Noida in Uttar Pradesh.

Importing specialised tooled-up machines alongwith jigs and fixtures for testing (kept ready at our collaborator’s facility in Korea), obtaining clearance from the Indian customs department and transporting the machines to our plant in Greater Noida in Uttar Pradesh

Preparing the plant to suit manufacturing requirements and ensuring an efficient work flow layout, in consultation with our collaborator Dongwon Metal.

Recruiting the best talent in the industry in a region that had experienced labour unrest. In addition, limited time constraints meant that trainers from Korea were brought in to train employeesin India and help with initial production lots.

Implementing best practices in every department, leading to the company receiving ISO 9001 certification in October 1996 itself. This was a special accomplishment, as ISO certification is usually granted only after evaluating performance over six months, which meant that systems were in place from day one.

Enabling the commissioning of the equipment in less than 72 hours working round the clock.

Success depended on immaculate planning and impeccable execution. Recognising this, Panalfa Dongwon executed a well-planned strategy to initiate production and supply within 56 days. It included:

Incorporating Panalfa Dongwon, with approval from the foreign investment promotion board, and identifying a plant in close proximity to our customer that was available on rent, as there was no time to build one. Further, all complex and time-consuming statutory registrations and approvals under various government departmentswereexecuted.

Importing completely knocked down (CKD) parts from collaborators, receiving clearance from the Indian customs department and transporting these parts from Mumbai to our plant in Greater Noida in Uttar Pradesh.

Importing specialised tooled-up machines alongwith jigs and fixtures for testing (kept ready at our collaborator’s facility in Korea), obtaining clearance from the Indian customs department and transporting the machines to our plant in Greater Noida in Uttar Pradesh

Preparing the plant to suit manufacturing requirements and ensuring an efficient work flow layout, in consultation with our collaborator Dongwon Metal.

Recruiting the best talent in the industry in a region that had experienced labour unrest. In addition, limited time constraints meant that trainers from Korea were brought in to train employeesin India and help with initial production lots.

Implementing best practices in every department, leading to the company receiving ISO 9001 certification in October 1996 itself. This was a special accomplishment, as ISO certification is usually granted only after evaluating performance over six months, which meant that systems were in place from day one.

Enabling the commissioning of the equipment in less than 72 hours working round the clock.

The

Panalfa edge

In less than two months of forming Panalfa Dongwon, we achieved “complete assembly process localisation” and initiated supply to Daewoo Motors, meeting the March 31 deadline.The first assembly was completed on March 28, 1996 and sent for final testing and approval to the customer. Panalfa Dongwon received approval and the first lot was despatched on March 30, 1996—one day before the target.

The same speed and immaculate planning was replicated in execution and Panalfa Dongwon successfully met its next target of “complete manufacturing process localisation” by September 30,1996. It involved more elaborate operations, but with the help of an efficient team, Panalfa achieved the next level of success and despatched the first lot of products that had been completely locally manufactured on September 4, 1996.

As a result, Daewoo was able to meet the localisation targets stipulated by the government and gained competitive advantage quickly. At the same time, Panalfa Dongwon was the first company in India to supply complete exhaust systems to an original equipment manufacturer (OEM). Its top performance encouraged Daewoo Motors to broaden its product portfolio and include impact beams, tie bar assemblies, brace struts and pedal assemblies.